Stories

Stories

-

14

Why I joined HAECO

-

15

The apprentices

-

16

MET flyer

-

17

CV240

-

18

Mistakes & even more mistakes

-

19

Up in the air

-

20

When boss calls

-

21

Craftsmanship rules

-

22

Package matters

-

23

Seaplanes maintenance

-

24

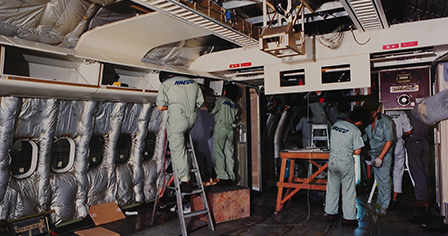

Reconfiguration

-

25

Fixing the gas tank

-

26

Tempting staff benefits

-

27

New business

-

28

747 inauguration

-

29

New is not enough

-

30

We rock the world

-

31

Lufthansa incident

30

Kelvin

Which type of aircraft was the strongest suit of HAECO in your time?

Cheung Kwok Kuen

In the 70s and 80s, our claim to fame was the Lockheed “TriStar”. We were undoubtedly first-rate in this…

The strengths of HAECO

Aircraft maintenance base was scarce in Asia at that time, and I dare say that all the aircraft models HAECO received were world famous. Let’s say CV-880 and CV-990; they were few in the industry, and HAECO was one of the primary maintenance factory for them. Cathay Pacific bought a lot of “TriStars”, so HAECO had been the world’s most famous maintenance factory for this type of aircraft.

Liang Yee Ming

The relationship between “TriStar” and HAECO was especially intimate…

HAECO made the TriStar a classic aircraft

“TriStar” wouldn’t be able to exist for so long without HAECO. Its structure was good, but the designers failed to put into account the problem of rusting in the future. So they needed constant and frequent repairing and belly replacement, etc. Other companies lacked the skill, but the Sheet Metal Department of HAECO was capable of doing it.

Au Sung Lai

“TriStar” was really a classic in the history of aviation…

The weaknesses of TriStar

“TriStar” was very new and massive. When there were only one or two systems in other planes, it had a lot of systems add-on, three after three and so on. And it had other systems like electronic games and entertainment, etc.

Cheung Kwok Kuen

The strengths and weaknesses of TriStar

“TriStar” was made out of military plane technology. It was superb at that time in its automated systems. I was responsible for avionics, navigation and metering, and “TriStar” was remarkable in all these aspects. Its automatic guidance system was far more advanced than that of Boeing. But it was less hardwearing. The problem was, “TriStar” relied too much on electronics; even the toilet flushing sequence was controlled by logic system, which determined which toilet to flush. You have to know that aircraft maintenance was roughly divided into airframe, engine, mechanical engineering and avionics, but “TriStar” was always at the halfway point. Those that used to be purely mechanical were joined by electronics, so the mechanical engineers had much complicated works to do and it was difficult for them to get the drift. Similarly, the avionics engineers were weak at mechanics. That means it was a strike for both the avionics and mechanical specialists.

Yiu Yu Tim

What the hey, “TriStar” was really ridiculous…

The ridiculous problems of TriStar

“TriStar” applied electronics even on toilets. The logic system controlled all five toilets on the plane, and it was prone to malfunctioning. We received complaints all the time; there were over 200 passengers and only two toilets were usable. “TriStar” was made of residual materials of the U.S.space technology. It was simply absurd for them to use circuit boards on almost everything. I just thought it was a waste. Every single thing was integrated circuit, and every single thing went wrong easily. Even the toilet flush button used logic. When you hit it often enough, it ceased to work. All the worse, they sent us the most thorny “TriStar”, especially for engine overhaul. Rolls Royce sent the easy one to Singapore and left the puzzle to HAECO, because Hong Kong workers were smarter and more ingenious.